Seam Stress? Solutions for Quilters

Reading time: 11 minutes and 6 seconds

April is National Stress Awareness month. Most of us think about stress in terms of our lives outside of quilting. Family, work, social pressures can all contribute. As quilters, we usually think of our creative work as relaxing, right? At least until those tiny pieces don’t fit together quite right, and we have to have a date with “Jack” the seam ripper. One of the biggest contributors behind those stressful sessions with Jack is problems with seams.

The good news is that most of the causes of seam stress are fixable with a bit of know-how and practice. Let’s explore some common seam issues, understand why they happen, and learn practical ways to address them.

Quilting's Holy Grail: the 1/4-Inch Seam Allowance

Why It Matters:

Bottom line, seam allowances affect the size of your finished quilt blocks. If the seam allowance is too large, your blocks will be too small; too small, and they’ll be too big. Consistency is crucial to ensure that all your pieces fit together properly.

Common Mistake:

Beginners often struggle with maintaining a consistent seam allowance, leading to mismatched blocks and uneven quilts. Even experienced quilters will tell you they regularly check to make sure theirs is still accurate.

A friend of mine learned this concept the hard way when she was making her first quilt. She sewed the blocks into rows, then started sewing the rows together, but no two rows were the same length! Some were even off by multiple inches! Her inconsistent seam sizes compounded as each block went together. She spent a lot of time with Jack that weekend, but it drove the lesson of seam allowance home. Lesson learned!

How to Fix It:

There are a few tricks that you can use to help ensure your seam allowances are accurate. Here are a few:

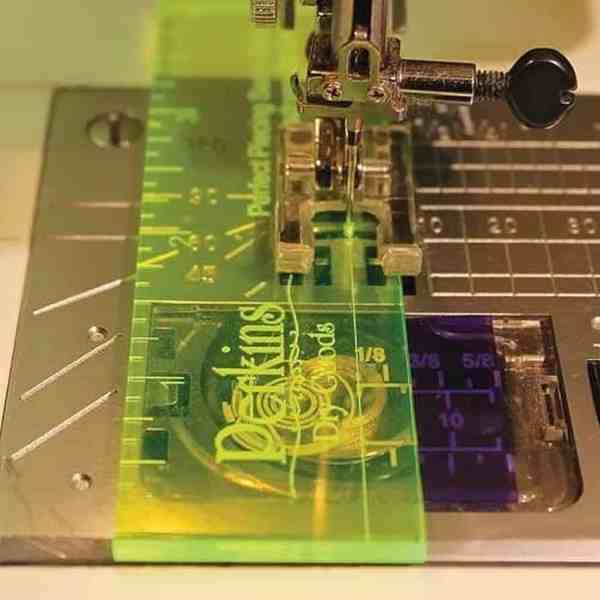

- Use a seam guide or a ¼-inch foot on your sewing machine to help keep your seams consistent. Measure from the tip of the needle to the edge of your guide or foot. There are rulers with holes that you can insert your needle in to help measure the 1/4 inch exactly.

- Some machines allow you to adjust the needle left or right by very small amounts if your foot or guide doesn’t give you accurate results. Not all machines have this feature, though–check your user manual.

- Inaccurate pressing can cause the pieces and seams to stretch. The proper technique is to lift the iron up off the ironing surface and move it to the next location. Also, using steam in your iron might cause stretching. Try using a dry iron instead if you experience that.

Puckered Seams

There’s nothing more frustrating than a puckered seam. You put so much effort into accurate cutting and the perfect 1/4-inch seam that it could make you cry if it’s lumpy or wavy. And nothing drives a longarmer crazier than a flimsy (aka quilt top) with puckers!

What Causes It:

The causes of inaccurate seam allowances can contribute to puckered seams. But there are a few more things to check:

- Thread tension that’s too tight can stretch the thread as it goes through the machine. When you’re done with the seam the thread will relax, causing the fabric in the seams to “pull up” and make wavy puckers.

- Stitch length that’s too short or too long can contribute to puckers. You need a much smaller stitch length for paper piecing than you do for standard geometric blocks, so double check this adjustment.

- Are your feed dogs adjusted to pull the fabric through the machine smoothly? If not, it could be pushing too much or too little fabric through for the speed you’re sewing, causing unattractive seams.

- Stretched fabric can cause all kinds of problems with your seams. Whether it’s trying to fit two blocks together that aren’t quite the same size, or trying to get fabrics to line up when sewing curves, stretching can exacerbate problems with seams and puckering.

Preventing the Problem:

- Check your iron’s temperature to help ensure the fabric isn’t stretching or shrinking due to excessive heat.

- Pin seams more frequently (closer together) so fabric doesn’t shift during sewing. (Whether or not to sew over pins is an entirely different discussion!)

- Try using a walking foot to help fabric feed through the machine more evenly. It’s not just for quilting everything together!

- Use a stay stitch (small stitches very close to the edge of the fabric) to help keep fabric from stretching.

Fixing Puckered Seams:

If none of that worked, all is not lost!

- Try pressing with a hot iron and some steam. Just remember to use the lifting technique and do not push the iron.

- Make a date with Jack, your handy seam ripper. He’s not much fun, but he gets things done! Start anew and try again.

Some quilters live by the mantra, “It will all quilt out (at the longarmer) in the end,” including puckers. (It’s not always true, and your longarmer may not love you if you send her puckers to start).

Addressing fraying fabric

Frayed fabric in your seams can weaken your quilt, leading to holes or tears over time. This issue is particularly common when working with fabrics like loosely woven cotton or linen. It can also happen if you try correct a block’s size when sewing them together by reducing the seam size to be smaller than 1/4 inch. The stress of every day use can weaken those seams, leading to fraying and sometimes even seams manifesting holes.

Identifying the Problem:

You might notice threads coming undone at the edges of your fabric even before you make a seam. Fabric that’s fraying can look like the the scarves that have some of the edges fringed. The seam then becomes weak because there are fewer threads to stabilize it.

Preventing Fraying:

To prevent this, consider using a zigzag or overlock stitch along the edges of particularly delicate fabrics before piecing your quilt. Even a stay stitch around the edges of a piece can help. These all help secure the fabric and reduce fraying.

Fraying can naturally happen around curves, but if it’s happening on straight cuts, make sure you align the fabric grain before you cut. Fabric grain runs in the same direction as the selvedges. If you don’t cut either in the same direction as or perpendicular to the grain, it frays much more easily. It’s always a good idea to align the grain before you start cutting your pieces–sometimes the fabric isn’t aligned when it’s wound onto the bolt. (Don’t assume!) I always buy a few inches extra when I’m purchasing fabric for a specific pattern so I can do this. (Yeah, that’s my excuse!)

In a pinch you can use products like Fray Check liquid, but it’s difficult to apply evenly to small edges and it’s often very stiff when it dries.

Dealing with Frayed Edges:

If you encounter fraying after sewing, you might need to reinforce the seam by stitching over it again, using products like Fray Check, or consider attaching a lightweight fabric stabilizer to the block. If you choose the stabilizer route, it will probably affect the “drape” of your quilt.

Managing Bulk at Seams

Bulky seams can make your quilt difficult to work with, especially when sewing through multiple layers of fabric. If you’re quilting the sandwich together on your domestic machine, it can make things particularly difficult when trying to keep even stitches. (And yes, longarmers aren’t fond of bulk either.)

Common Causes:

Bulk at seams occurs when multiple seam allowances converge at one point, such as at the corners of blocks and can sometimes be caused when seams get pressed the wrong direction. Pinwheel blocks are notorious for having bulk where all eight points converge, and there are specific techniques quilters have devised to deal with them (check YouTube). Blocks should be pressed so adjoining seams go in opposite direction to reduce bulk. Many quilters call this “locking” the seams into place.

Reducing Bulk

Today patterns often show the direction to press the seams to help reduce bulk, so be sure to check. If it isn’t specified, most quilters press seams “to the dark side” (referring to fabric value), but some will press seams open to help deal with bulk. Pressing seams open is the accepted technique for clothing, but in quilting pressing to the side is seen to have the advantage of strengthening seams. If there is too much thickness at a junction, it can lead to broken needles, skipped stitches, or an uneven quilt top.

Sewing Through Bulk:

If you’re struggling to sew through bulky seams, try using a larger needle or a walking foot. Going slow and steady can also help prevent skipped stitches and broken needles. For particularly bulky seams, I will sometimes even manually feed the fabric through using the fly wheel.

Happy Seams to You

Seam issues are a common part of the quilting journey, but with a bit of knowledge and practice, they can be easily managed. By understanding the root causes of these problems and knowing how to address them, you can improve the quality of your quilts and enjoy the process even more. Remember, quilting is as much about learning from mistakes as it is about creating beautiful, lasting pieces. So don’t be discouraged by seam issues—use them as an opportunity to refine your skills and grow as a quilter. For more tips and tricks about sewing, quilting, and technology, be sure to check out my other blogs here! Happy quilting!

Hey there, I’m Theresa, The AI Quilter. I’m here to help you connect technology and creativity in ways that feel human, creative, and completely your own.

Explore More Topics